ॐ श्री गणाधिपतये नमः

ॐ श्री गुरुभ्यो नमः ॐ श्री शिवानन्दाय नमः ॐ श्री चिदानन्दाय नमःॐ श्री दुर्गायै नमः

Source of all Images in this Blog-post : Google Images : ‘Google Image Search’ will reveal the multiple sources of every single image shared here. For more details, kindly see ‘Disclaimer‘

Madurkathi mats, or Madur, are mats woven in the Indian state of West Bengal from a reed called Madur Kottir, or Madurkathi – a sedge of the family Cyperaceae.

Introduction:

Welcome to the enchanting world of Madurkathi mats, a splendid testament to the rich cultural tapestry of rural Bengal. These mats, woven with the magic of tradition and skill, are more than mere artifacts; they are a vibrant narrative of Bengal’s rural craftsmanship. In this blog, we will embark on a journey through the narrow lanes of rural Bengal to uncover the history, artistry, and cultural significance of Madurkathi mats, exploring how this traditional craft has woven its way into the fabric of Bengali life and beyond.

Madur mat-making, a craft deeply embedded in the cultural ethos of Bengal, particularly thrives in the Medinipur district. This traditional skill, passed down through generations, plays a pivotal role in the rural economy. The artisans, predominantly women, skillfully weave these mats using locally sourced Madurkathi reeds, showcasing a blend of durability and artistry. The process is not just about creating a product; it’s a celebration of heritage, sustaining families and communities while keeping alive a craft that is intrinsically linked to the identity and rhythm of rural Bengal.

Madurkathi mats, primarily crafted by the skilled hands of the Mahishya caste weavers, are predominantly the domain of women artisans. This cottage industry is not just a cultural emblem but a vital source of income for village households in rural Bengal. Women, who are the mainstay of this craft, meticulously weave these mats, blending tradition with their livelihood. Their dedication and skill not only sustain their families but also preserve a craft that is integral to the region’s heritage. This industry, therefore, stands as a testament to the empowerment of women and the preservation of traditional arts in rural economies.

In Bengal, the word Madur is commonly used as a generic term for floor mats, although it specifically refers to mats woven from a distinct type of reed. This reed, known for its durability and flexibility, is integral to the unique texture and quality of Madur mats. The term embodies not just the physical object but also the rich cultural and artistic tradition behind its creation. These mats, crafted with precision and care, are more than just functional items; they are a celebration of a time-honored skill deeply ingrained in the cultural fabric of Bengal.

Mats are an integral part of the social fabric of rural Bengal, and Madurkathi mats, in particular, are widely popular for their versatility. Commonly used for sitting and as bedding, these mats are not just daily necessities but also a symbol of hospitality and tradition. In many households, they serve as a humble yet dignified setting for various social and familial gatherings, seamlessly blending into the rhythm of daily life. Their functionality, coupled with the aesthetic appeal, makes Madurkathi mats a cherished element in the homes of rural Bengal.

Functional Benefits of Madurkathi Mats

Madurkathi mats are valued for their non-conductive and sweat-absorbing properties, making them an indispensable item in the hot and humid climate of West Bengal. These characteristics contribute significantly to their comfort and practicality in daily life. Additionally, they hold a prominent place in religious practices, being widely utilized for various ceremonial and spiritual purposes.

On March 28, 2018, Indian Patent Office granted the Government of West Bengal a Geographical Indication (GI) Tag for Madurkathi.

Modern Adaptations of Madurkathi Mats

In response to the evolving demands of the modern market, there has been a significant shift in the traditional crafting of Madurkathi mats. Artisans have been adapting their techniques to create a broader range of products, thereby extending the utility of Madurkathi beyond its conventional form. Key adaptations include:

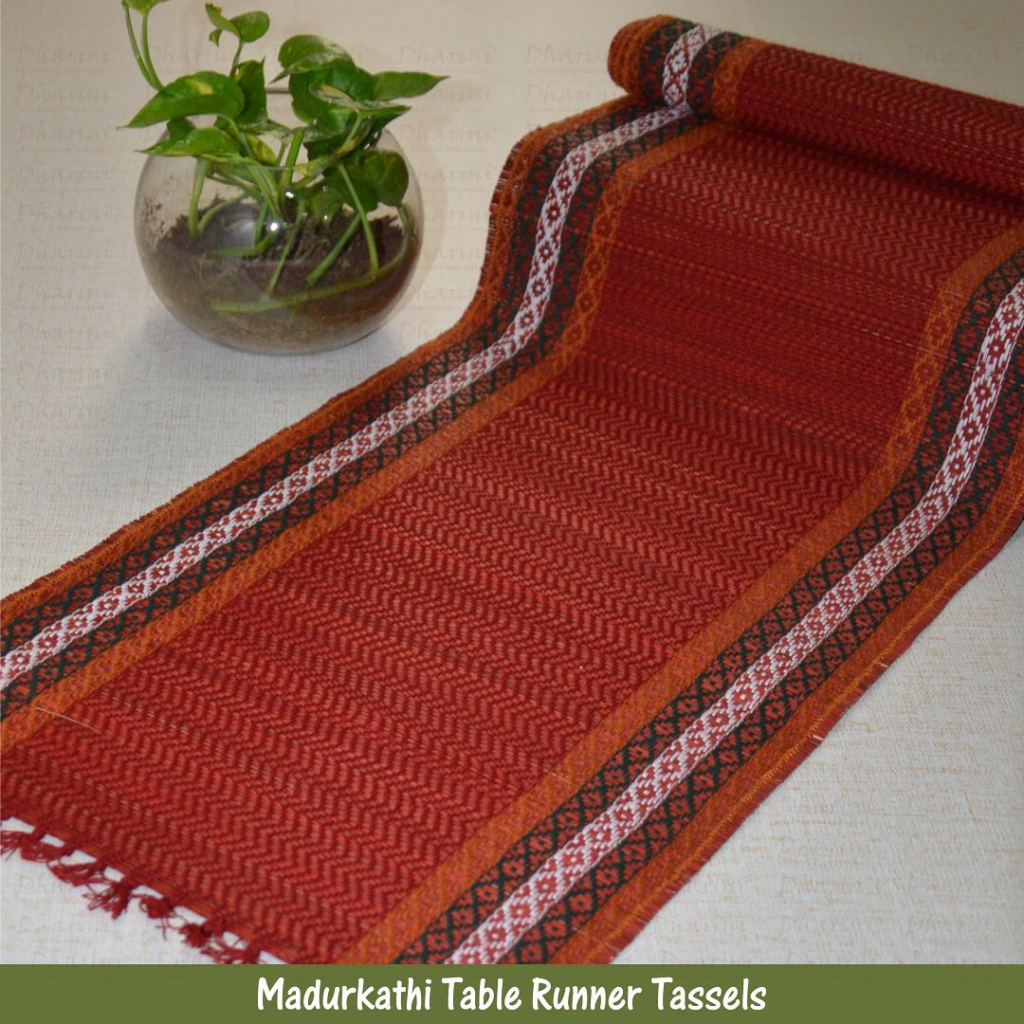

- Diversification into Home Decor: Weavers have started using Madurkathi to craft elegant door curtains, blending traditional weaving techniques with contemporary designs. These curtains not only add a rustic charm to modern homes but also serve as a testament to the versatility of Madurkathi.

- Fashion and Utility Items: The adaptability of Madurkathi has been further showcased in the creation of fashionable and functional items like handbags. These handbags are not just eco-friendly but also merge traditional craftsmanship with modern aesthetics, appealing to a wider audience.

- Decorative Items: Artisans are crafting a range of decorative items using Madurkathi. These include wall hangings, coasters, and other ornamental pieces that cater to the growing demand for sustainable and ethically made home decor.

- Innovative Uses in Everyday Life: Beyond decor and fashion, Madurkathi is being utilized to make practical items like tiffin-carriers, placemats, and even furniture accents, offering durability and a unique style.

These modern adaptations signify a shift in the perception and application of Madurkathi weaving. By branching out into various domains, artisans are not only keeping the tradition alive but are also ensuring its relevance and appeal in a rapidly changing world. This innovation also opens up new economic avenues for the weavers, contributing to the sustainability of their craft.

Varieties of Madurkathi Mats

Madurkathi mats, primarily crafted by Mahishya weavers, come in three distinct types:

- Ekh-rokha (Single Mat): This is a lightweight, thin Madur mat.

- Do-rokha (Double Mat): Heavier and thicker than the Ekh-rokha, the Do-rokha offers enhanced comfort and utility.

- Masland: The most refined and costly among the three, Masland mats are textured and feature decorative patterns.

Beyond these mats, Madurkathi is also utilized to create a range of both decorative and practical items, such as door curtains, sleeping mats, tiffin-carriers, and handbags.

Madurkathi Cultivation

Madur mats are crafted using the sedge Cyperus pangorei, known as Madurkathi. This plant thrives in the marshlands of southern and eastern India, particularly around Medinipur. The region’s frequent floods render many areas unfit for conventional farming. Consequently, the cultivation of grasses, sedges, and reeds, like Madurkathi, offers a practical substitute for the local farmers. This practice has evolved into a significant occupation, providing a vital source of income for the community through the weaving and sale of Madur mats.

Colouring Process of Madurkathi Mats

Madurkathi mats feature natural reed hues woven into geometric patterns, creating subtle designs. These mats are traditionally coloured using vegetable dyes. For additional embellishment, especially on the borders, natural maroon or black dyes are applied.

Black Dye: This is prepared from Haritaki fruit (Terminalia chebula) and the fruit and bark of the Babla tree (Vachellia nilotica).

Red Dye: Derived from the seeds of the Achiote or annatto tree (Bixa orellana), this tree, originally from Latin America, was introduced to India during the 16th and 17th centuries. In West Bengal, it’s known as Rang Gach. It’s mainly cultivated for its dye.

Dyeing Process: Before dyeing, the mat sticks are tightly wrapped in palm leaves to preserve their natural colour in specific areas. These bundles are then placed in containers with dye powder and cold water, which are subsequently boiled. The boiling duration varies with the colour desired: 10 hours for black and 24 hours for red. Post boiling, the dyed mat sticks are sun-dried before weaving.

Conclusion:

As we conclude our exploration of the woven magic of Madurkathi mats, we find ourselves deeply entrenched in the cultural legacy of rural Bengal. These mats, a product of meticulous craftsmanship and cultural heritage, are not just utilitarian objects but symbols of a rich, enduring tradition. Their story is a resilient testament to the artistry and ingenuity of rural Bengal, reminding us of the profound beauty and significance that traditional crafts hold in our world. Madurkathi mats stand as a proud declaration of cultural identity, artistry, and the unspoken narratives of rural Bengal.

Explore on Amazon India & Shop Now

One reply on “The Woven Magic of Madurkathi Mats: A Cultural Legacy of Rural Bengal”

thanks for sharing nice content. good website